Business content

Civil engineering

Civil engineering

We are working on infrastructure development

to create the environment of the future.

Public works and residential land development

Public works and residential land development

We also transform underutilized forests and farmland into attractive residential land, and develop residential land to increase asset value. Public works require specialized knowledge, experience, and research into the latest technology, and building land for housing involves the risk of landslides and landslides. For this reason, our highly experienced and highly skilled professional staff will respond promptly.

-

Mikitakami, Minami-ku, Sakai City and Oike Residential Land Development Project -

Fiscal 2013 Road improvement work associated with JR Yao Station area development project -

Higashi River System Higashi River No. 2 Branch Sabo Dam Development Project (Phase 3) / Gravity Concrete Sabo Dam -

FY2022 No. 10 No. 2 Multi-purpose domestic trade quay ground improvement work

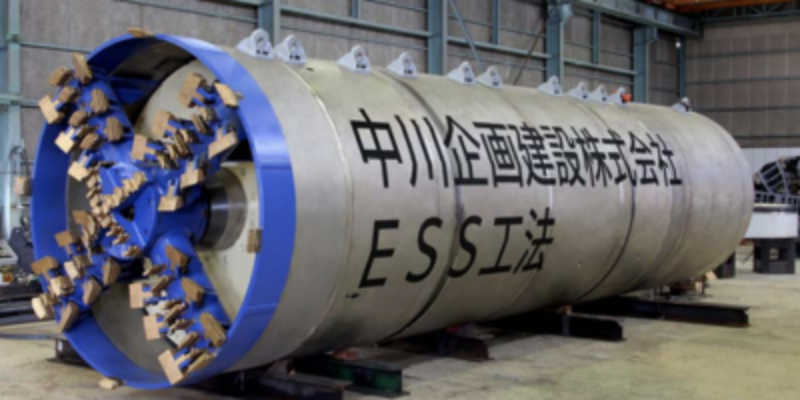

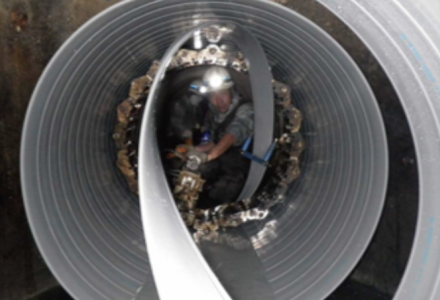

Tunnel construction (ECO SPEED SHIELD construction method)

We have developed the ECO-SPEED-SHIELD (ESS) construction method, which combines the jacking method and the shield method, in order to eliminate environmental problems such as water pollution and increased waste due to rapid economic growth and urbanization. Then, we established the ESS Association for the utilization of the ESS construction method. Using this ESS as a trump card for infrastructure development (water supply and sewerage, gas, electric power, communications, etc.), we are expanding our business with an eye on overseas markets.

ECO-SPEED-SHIELD (ESS) construction method

This technology is registered in the New Technology Information System (NETIS) of the Ministry of Land, Infrastructure, Transport and Tourism. (KK-170056-A)

-

Expected effect

- Improving the water environment by improving water supply, sewerage, agricultural and industrial waterways, and utility pipes

- Realization of urban development that is resistant to flooding

- Dissemination of clean construction technology, implementation of economical all-weather construction without traffic restrictions and large construction yards

-

Feature

- Long-distance propulsion technology for curves exceeding 1 km, non-cutting technology

- High-quality design, machine manufacturing, construction supervision technology

- Lineup to meet various pipe diameter needs from small diameter (800mm) to large diameter (3m)

- Curve construction at a sharp curve (radius 10m) (no intermediate shaft required)

- Improved economic efficiency (20%): less total loss of the excavator and can be diverted

- Fixed facilities and work space are about 1/3 of conventional technology

-

Patents and utility models for products and technologies

- Patent No. 5476057 Sediment discharge method and sediment discharge device in pipeline construction

- Patent No. 5537850 Sediment discharge method in sewer construction and trobucket for carrying out sediment used for this method

- JP2016-199903A Construction method of pipe, pipe and excavator

- Utility model registration No. 3193061 Connection pipe (shared by Kurimoto Concrete Industry Co., Ltd.)

Disaster countermeasures

In recent years, many large-scale earthquakes have occurred around the world, and Japan is no exception. In order to provide safety and security to our customers by taking countermeasures against earthquakes, we select appropriate construction methods from a variety of countermeasure methods and take measures against various disasters such as earthquake resistance, liquefaction, and slope collapse.

Seismic measures

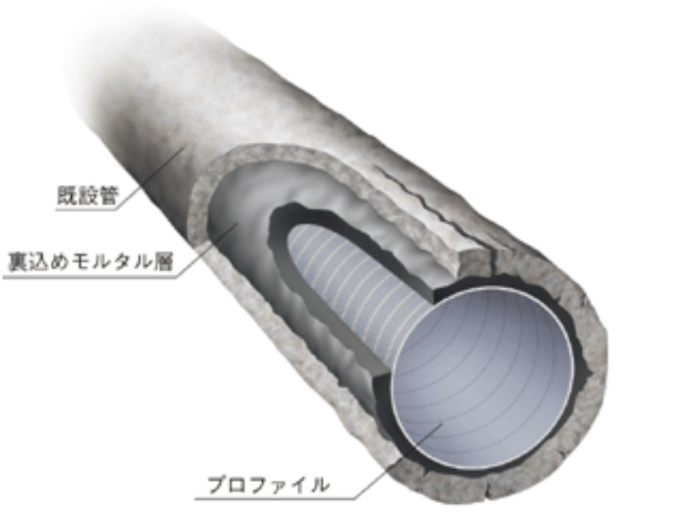

SPR (Sewage Pipe Renewal) method for reviving aging existing pipes

By manufacturing a rehabilitating pipe with a hard vinyl chloride profile inside the existing pipe and filling the gap between the existing pipe and the rehabilitating pipe with a special backfilling material, the old pipe can be used as the existing pipe, the rehabilitating pipe, and the backfilling. It is a construction method that can be revived as a strong composite pipe in which the materials are integrated.

-

Feature

-

Can be constructed without digging up the road

Since all the equipment is put into the pipeline from the manhole, construction can be done without digging up the road.

There is no generation of waste such as earth and sand due to no excavation.

-

Compatible with any cross-sectional shape

It supports all cross-sectional shapes including circular, rectangular, and horseshoe.

- Can be constructed while running water

- Long-distance construction and curvilinear construction are possible *Limited to self-propelled type

-

Possible to make pipeline facilities earthquake resistant

It is ideal as an earthquake-resistant measure for sewers between evacuation facilities and treatment plants, under important roads such as national highways, and under railroad tracks.

-

Work can be interrupted even during tube making

Work can be interrupted even during sudden torrential rain. You can also resume work by connecting profiles.

-

Can be constructed without digging up the road

Re-pipe system (pipe line rehabilitation) construction method

Considering the existing pipeline as a system rather than a single pipeline, we are responsible for design and construction from investigation and diagnosis to pipeline rehabilitation and pipe cleaning. (-From Research to Reborn-)

By forming a strong tag between a pipe material manufacturer and a construction company, we can demonstrate more synergy effects, and provide reliable quality and high technology to meet various needs and problems related to maintenance and management, renewal and rehabilitation of pipelines throughout the country. I will do my best to respond.

-

Five rehabilitation methods owned by the Re-Pipe System Construction Method Association

-

KU-LINER® method

-

CIPP method (under development)

-

Thin FRPM pipe-in-pipe construction method

-

Horseshoe-shaped FRPM pipe-in tunnel construction method

-

L-PIP method

-